A Comprehensive Guide to Understanding Litho Printing Techniques

The world of litho printing, a method originating from the late 18th century, is a fascinating mix of background, science, art and advancement. This comprehensive overview will certainly decipher the complexities of this printing technique, from the structure of litho inks to the difficulties dealt with in modern-day applications. As we venture right into the ins and outs of lithography, the relevance of automation and sustainability in ensuring its future importance comes to be significantly clear. Remain with us as we journey right into the captivating realm of litho printing.

The Historic Advancement of Litho Printing

The historic trajectory of litho printing, a pivotal technology in the realm of interaction, is a fascinating story of human ingenuity. Birthed in the late 18th century by Alois Senefelder, this method was originally a cost-effective method of releasing theatrical works. Lithography, originated from the Greek words for 'stone' and 'to write', used a smooth stone surface area to transfer photos onto paper. The procedure evolved with the development of the rotary press, which considerably enhanced productivity (litho printing). In the 20th century, the technology of balanced out lithography reinvented the industry, allowing for automation of premium prints. Each stage of litho printing's development showcases mankind's ruthless quest of efficiency and quality in visual interaction.

Translating the Scientific Research Behind Litho Printing Inks

Progressing in the exploration of litho printing techniques, the emphasis now moves to the scientific research behind litho printing inks. The structure of these inks, their drying process, and color mixing techniques develop the backbone of this complicated art type. Understanding these components is crucial to mastering the craft and attaining the preferred print outcomes.

Structure of Litho Inks

In lithographic printing, the fundamental role of litho inks can not be overemphasized. The structure of litho inks differs depending upon its purpose, however normally, they contain 2 major elements - pigments and automobiles. Pigments, the color-providing aspects, are carefully ground bits suspended in the automobile, a fluid that carries the pigment onto the printing surface area. The automobile is a complicated mixture of solvents, materials, and oils, which influence the ink's drying out time, bond, and gloss. Additionally, various ingredients are present to enhance specific homes like flow, drying, and resistance to ecological results. Each component plays an important component in the last print's top quality, making the specific formulation of litho inks a complex scientific research.

Ink Drying Refine

From the structure of litho inks, focus turns to the interesting procedure of ink drying. The drying process is crucial, as it impacts the final print's top quality and longevity. 2 key methods are utilized in litho printing: oxidative drying and absorption. Oxidative drying out includes the ink reacting with oxygen airborne to create a hard, completely dry film. This technique gives a durable finish, however can be slower compared to absorption. Absorption, on the various other hand, includes the ink permeating right into the paper fibers, which is a quicker process but can result in less vivid colors. The selection in between these approaches is dependent upon elements such as print speed demands, the paper kind made use of, and the wanted surface.

Color Combining Methods

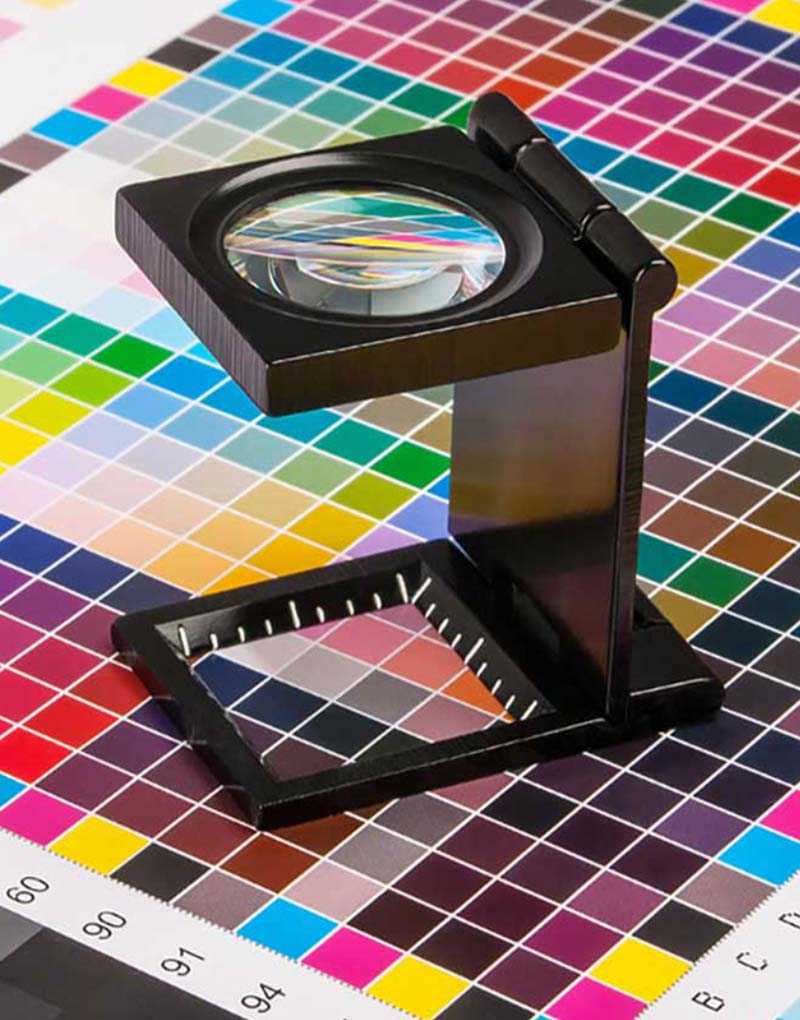

While the drying out procedure plays a key duty in litho printing, the science of shade blending methods holds equivalent relevance. This is an intricate process that includes the careful mixing of primaries: cyan, magenta, and yellow, in differing proportions to attain a vast selection of shades. The enhancement of black ink, understood as 'crucial', helps in regulating the intensity and deepness of the colors. The scientific research behind litho printing inks likewise considers the transparency of the ink, which influences how colors overlay and mix. To attain an efficient color mix, print specialists must additionally recognize the ins and outs of ink actions, color concept, and the physical residential or commercial properties of the substratum on which the ink is applied.

The Art and Style Aspects in Litho Printing

Litho printing breathes life right into art and layout through its special aspects. The procedure involves producing a photo on a lithographic limestone plate or metal plate with a smooth surface. The photo is then printed onto a medium, usually paper, by transferring the ink from home plate. What sets litho printing apart is its capacity to reproduce elaborate layouts with high integrity, making the output nearly the same to the initial artwork. This is accomplished via making use of different line methods such as cross-hatching, check it out stippling, and hatching, which permit a variety of tonal results. Litho printing fits a selection of shades, allowing musicians to create dynamic and lively prints. This mix of accuracy and adaptability makes litho printing a recommended selection for many artists and designers.

Modern Applications of Litho Printing Strategies

Litho printing strategies have located substantial use in the modern-day industrial market. Its influence and relevance remain to expand with the introduction of new advancements and innovations in the field. This area will discover these contemporary applications and the transformative role they play in the printing industry.

Industrial Litho Printing Makes Use Of

In today's digital age, one may question the relevance of conventional printing methods. Litho printing continues to be an important part of the industrial field. High-volume printing tasks, such as the manufacturing of publications, papers, and product packaging, rely on litho printing for its capability to supply exceptional photo quality and cost performance. The process, which involves moving a tattooed picture from a plate onto a rubber covering and then to the printing surface, supplies unmatched uniformity. This makes it optimal for work calling for a big print run. Litho printing also offers a wide color spectrum, above that of electronic printing. This makes it the best selection for jobs that require lively, premium shade reproduction.

Developments in Litho Printing

Pressing the limits of standard methods, modern innovations have actually sustained a host of developments in litho printing. One famous growth is digital litho printing, which integrates the virtues of electronic modern technology with litho's high-quality output. These developments emphasize the enduring significance of litho printing in the contemporary globe.

Checking out the Process of Litho Printing: Step by Step

Challenges and Solutions in Contemporary Litho Printing

Despite the precision and custom that litho printing happily upholds, it is not without its set of contemporary obstacles. Digital litho printing allows for cost-effective brief runs and easy personalization, attending to the problem of variable data. Therefore, while there are challenges, the litho printing market is proactively adjusting to fulfill them head-on, ensuring its significance in the future.

Verdict

In conclusion, litho printing, with its rich background and clinical ins and outs, holds a considerable area in the print industry. As the overview exposes, it's a synthesis of art and technology, with modern advancements guaranteeing its importance. Nonetheless, the industry faces obstacles that call for innovative options, with a concentrate on automation and sustainability. The future of litho printing depends upon its capacity to adapt to these transforming demands, attesting its long-lasting worth in an evolving market.